Sewer Mining sounds like dirty work, but it can be a sustainable answer to a nasty problem. Existing sewer infrastructure in urban areas is vastly becoming overwhelmed and in need of relief from excess volumes and high energy consumption. In some cases such as in Dubai, United Arab Emirates and the building of the Burj Khalifa tower; sewer pipe infrastructure does not exist or has been delayed. The delivery of wastewater becomes a growing logistics challenge described in the video below.

There is a solution to such overwhelming problems: sewer mining. A holistic and passive linear waste water treatment technique by EPIC that can compliment sewer treatment plants. The excess volumes can be distributed for subsurface use in parkways, landscapes, and greenbelts. The search for the future reuse of water is as far as the bathroom. What is golden is that sewage water can be reused without clogging, without bad smells, and help sustain beautiful landscapes without human exposure. The birthplace of the EPIC system.

In the 1980s, Jonas Sipaila invented the Environmental Passive Integrated Conveyance (EPIC) system as an alternate septic leach line apparatus and method. EPIC was later patented by Sipaila in 1999. Jonas witnessed numerous septic leach lines as a county public health inspector in the State of New York. As a biologist and a chemist, he knew the most efficient microbiological degradation occurs in the top layer of soil. In well drained soils, abundant oxygen helps the microbes thrive. The challenge Sipaila solved was how to get the moisture to move backwards, upward and against the force of gravity. The secret was sand.

One day after a rain storm, Jonas noticed a pile of sand wicking up moisture from rain puddle. Eureka! Sand can move water upwards, the new challenge was how to build a pipe conveyance that integrates with sand. In time, the EPIC chamber is created to resolve the problem with offset holes that do not clog in a sand profile. EPIC is a superior septic leach field that self cleans by the aerobic sand profile that holds the surface area and the oxygen needed for strong microbiological activity. An automatic switching box with a dual pipe system alternate the EPIC flow lines every 6 months to alleviate any bio-mat buildup.

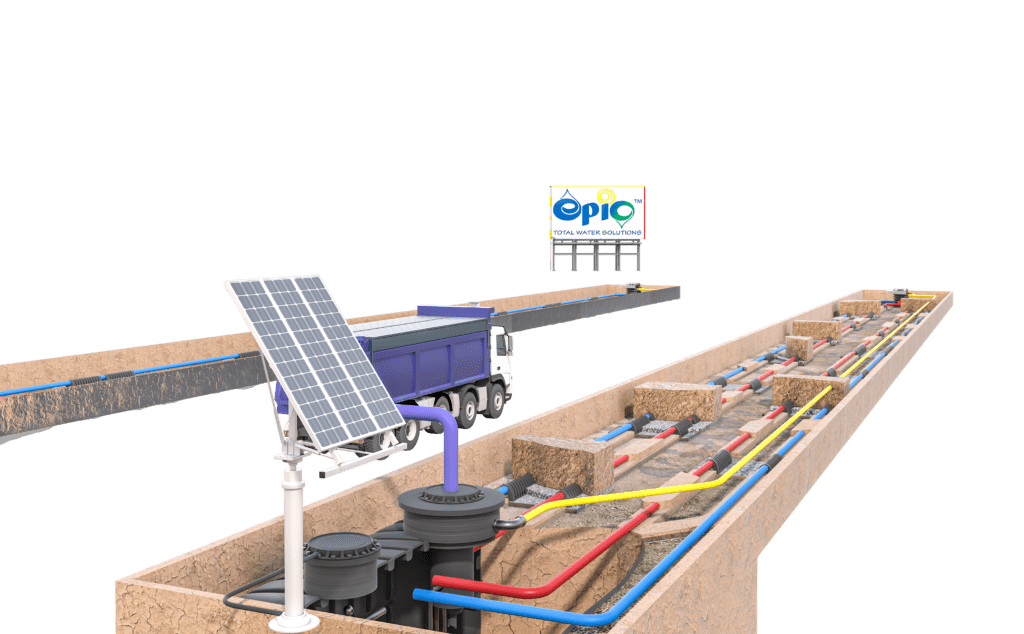

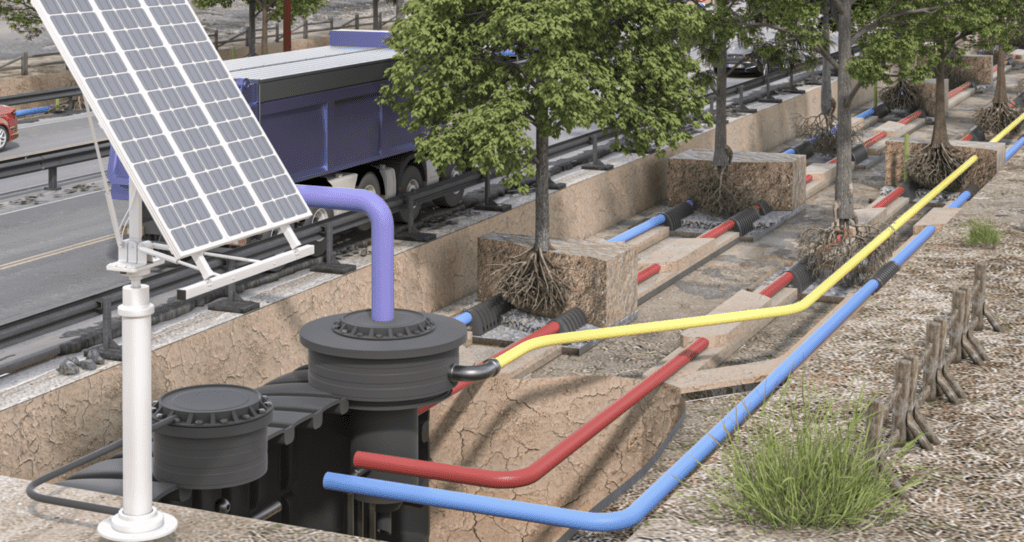

An example of roadside sewer mining is shown above. The yellow pipe servers as the re-circulation line between the pump and the EPIC inlet. The EPIC system operates by gravity, interfacing with the landscape growth profile through EPIC chambers connected by non-pressurized connector pipes. The black water is pumped upstream and to flow by gravity back to the pump. Nutrients and moisture are absorbed by the landscape without human exposure. This method helps alleviate reclaimed water treatment processes and reduces excess volumes at the treatment plants. The method is low tech and low energy, operating remotely from a solar panel. These EPIC sewer mining systems can be setup in adjoining roadside areas near waste water treatment facilities, or where wastewater can be intercepted or delivered.

Comparison of EPIC system with and without landscape layers

Aerial comparison of EPIC system with and without landscape layers

The EPIC system tests at the Walnut Creek waste water treatment plant and UC Davis Geo-Technical facility yield great successes. Various EPIC septic and grey water reuse installations have been installed in the United States. Many of these installations have decades of use history without the abandonment of the original EPIC leach line. EPIC can offer sustainable solutions to alleviate excess sewer volumes and save massive amounts of energy used at conventional municipal wastewater treatment facilities.

The PDF link below illustrates a patent pending design layout for removal of the solids, as an alternative to using standard septic tanks and subsurface storage for sewer mining projects.

Sewer Mining Water Recycling and Storm Water Mitigation System